As part of this demonstrator students are involved in the fabrication of two linked engineering components, which are then assembled and tested.

The UCD Learning Factory facility includes a 5 axis computer controlled (CNC) machining centre (Mori Seiki), a CNC turning centre, and other machine tools, in conjunction with sample handling, metrology (CMM), high levels of process monitoring and “supply chain” interconnectivity using an RFID system. It thus helps to address industries need for interdisciplinary training in technologies related to advanced manufacturing processes. Its goal is to provide a new engineering educational experience that emphasizes the interdependency of ICT-enabling technologies and advanced manufacturing processes. The Learning Factory approach aims to achieve this through the integration of a practice-based curriculum and advanced manufacturing facilities. In order for existing staff involved in manufacturing as well as undergraduate students entering the market significant training is required. to the complex global supply chain, and through the product-service lifetime. This transformation will affect all business processes, from in-house operations.

#LEARNING FACTORY MACHINING SOFTWARE#

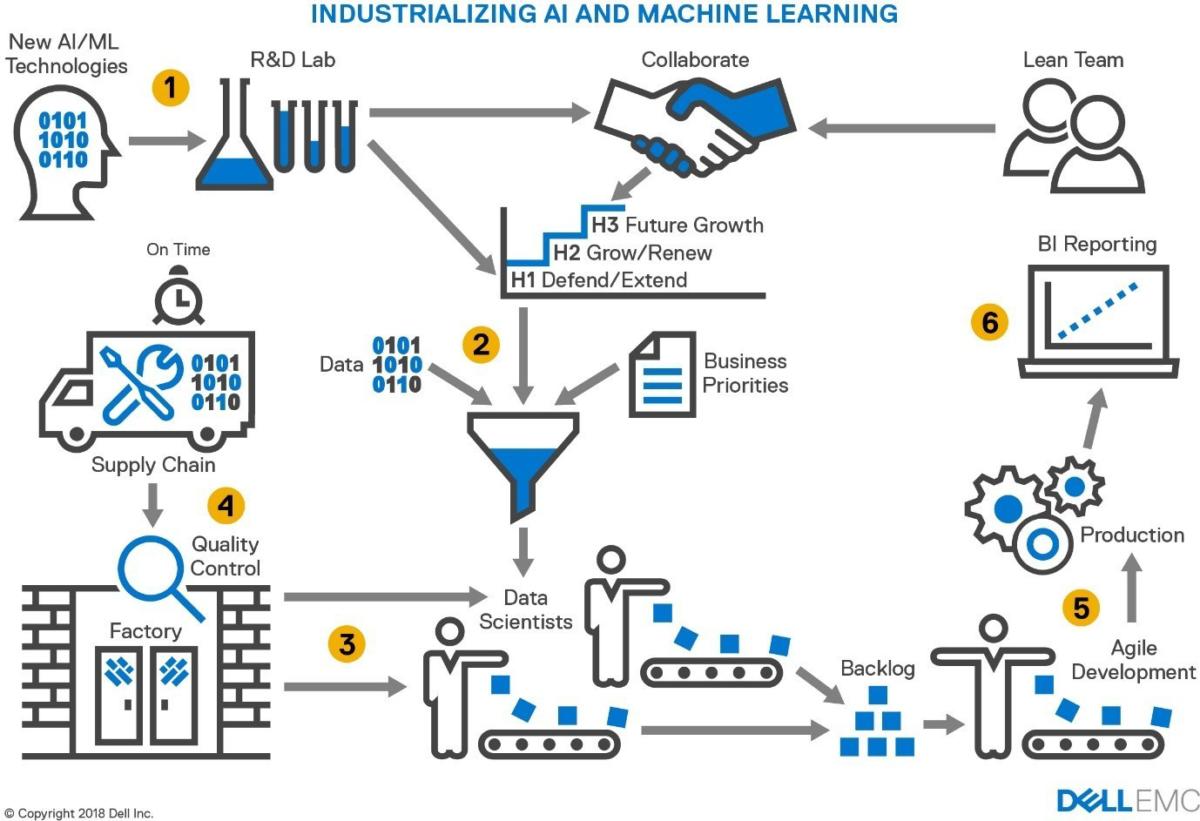

In addition there is the potential of integration through cloud computing, the application of advanced software such as data analytics, as well as interconnectivity through the “internet of things”. with higher levels of ICT-enabled technologies impacting on manufacturing processes. Manufacturing is currently undergoing a significant transformation.

0 kommentar(er)

0 kommentar(er)